In the modern agricultural and food processing industries, maintaining precision, quality, and efficiency is essential. The Ultra Trieur is a cutting-edge solution for separating grains and pulses based on size, shape, and length, helping businesses enhance product quality and meet industry standards. This machine plays a vital role in improving sorting accuracy while minimizing waste and manual labor. In this comprehensive guide, we will explore the Ultra Trieur, its features, working principles, applications, and the advantages it brings to various industries.

What is Ultra Trieur?

It is a rotary roller machine for precise separation of grains, pulses and seeds, eliminating foreign or undersized material. It is specially designed to separate products by circularity, diameter and length. It is widely used in grain processing plants, mills and agricultural facilities and ensures clean and high quality end products.

How Does Ultra Trieur Work?

It works using a rotary roller system that classifies products according to their size. Here is a step-by-step explanation of the working principles:

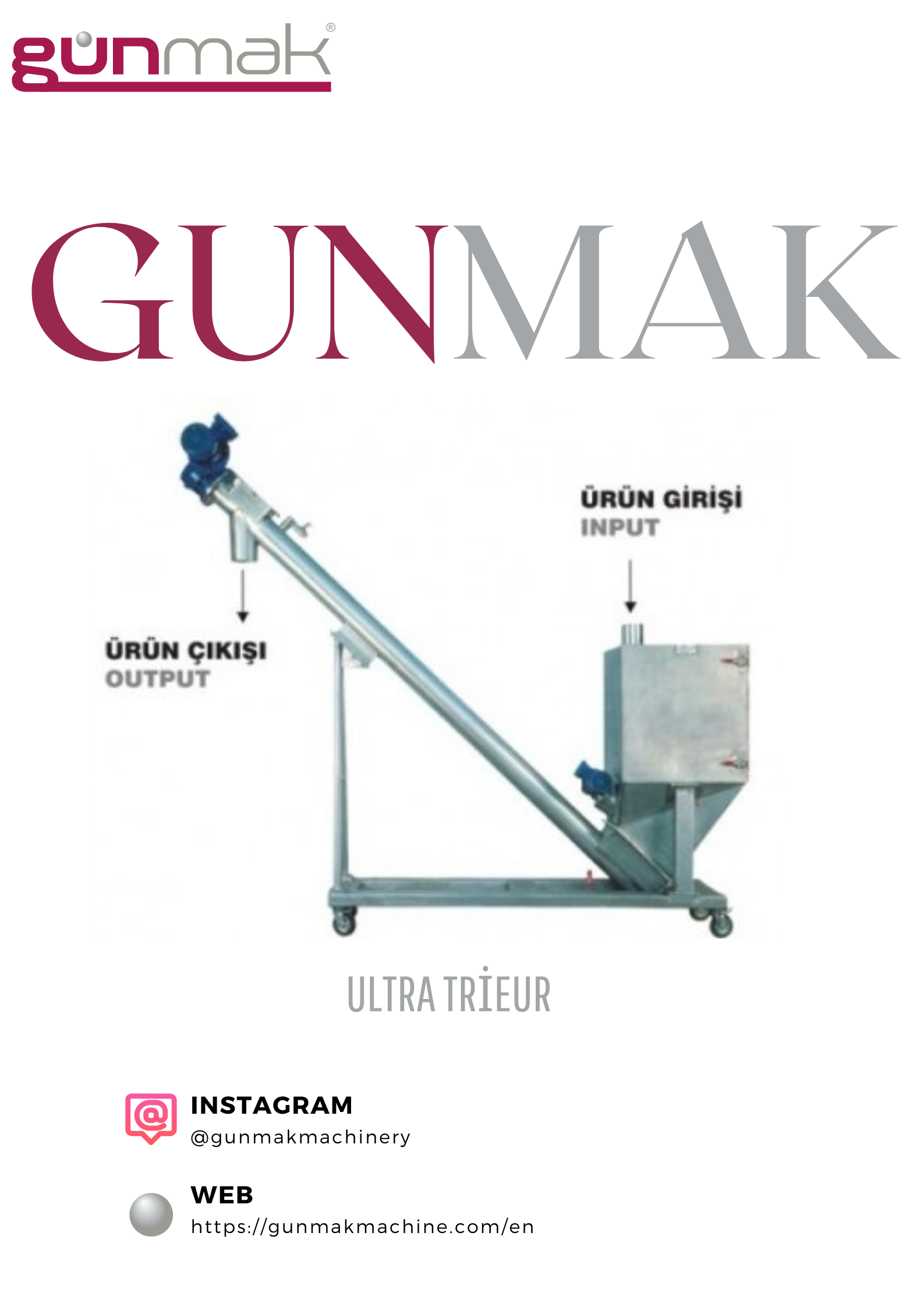

- Product Input: Grains or pulses are fed into the machine.

- Rotary Cylinder Mechanism: The rotary drum contains perforated surfaces with variable hole sizes that separate materials based on diameter and length.

- Adjustable Angle: The tilt angle of the cylinder can be adjusted for precise sorting, depending on the product type.

- Screw Conveyor Assistance: Separated materials are directed through screw conveyors for collection.

- Output: Cleaned and sorted materials exit the machine, ready for further processing or packaging.

The adjustability of the cylinder's mirrors and rotation speed ensures flexibility to meet different product specifications.

Key Features of Ultra Trieur

- High Sorting Accuracy: Separates materials based on annularity, diameter, and length with precision.

- Customizable Design: Available in single or double-cylinder models to meet varying capacity needs.

- Adjustable Parameters: Cylinder angle and rotation speed can be modified for different product types.

- Efficient Operation: Reduces manual sorting labor while maximizing productivity.

- Durable Construction: Made from high-quality materials for long-term durability and reliability.

- Low Maintenance: Easy-to-clean components ensure reduced downtime and maintenance costs.

Applications of Ultra Trieur

- Agriculture: Sorting grains such as wheat, rice, barley, and maize to remove foreign materials or broken grains.

- Food Processing: Ensuring uniform size and quality of pulses, lentils, and seeds for food production.

- Seed Processing: Cleaning and grading seeds to improve germination rates and quality.

- Milling Facilities: Ensuring raw materials are cleaned before entering the milling process.

- Recycling Plants: Separating materials for repurposing and processing.

Benefits of Using Ultra Trieur

- Improved Product Quality: Ensures clean, uniform, and contamination-free grains or pulses.

- Increased Productivity: Automates the sorting process, reducing the need for manual labor.

- Cost Efficiency: Minimizes waste and optimizes resource usage.

- Adaptability: Adjustable settings allow you to work with various product types and sizes.

- Sustainability: Reduces material loss and enhances processing efficiency.

Why Choose Ultra Trieur?

The Ultra Trieur stands out from traditional sorting machines due to its precision, durability, and efficiency. Whether you operate a large-scale mill or a small agricultural facility, this machine provides reliable performance and tailored solutions for your processing needs.

Frequently Asked Questions (FAQs)

What products can be processed with the Ultra Trieur?

Can process grains, pulses, seeds, and similar agricultural products to remove impurities and broken materials.Can the Ultra Trieur be customized?

Yes, it can be customized with single or double-cylinder models and adjustable angles to suit different product specifications.What makes Ultra Trieur different from traditional sorting machines?

The rotary cylinder mechanism offers higher precision in sorting based on size, shape, and length, making it more efficient and accurate.Is Ultra Trieur easy to maintain?

Yes, the machine is designed for low maintenance, with easy-to-clean components that reduce downtime.What industries use Ultra Trieur?

It is primarily used in agriculture, food processing, seed processing, milling, and recycling industries.

Conclusion

The Ultra Trieur is a versatile and efficient solution for precision grain and pulse separation. With its customizable features, advanced rotary cylinder mechanism, and ability to process various agricultural products, it is an essential tool for improving product quality and operational efficiency. By integrating it into your production line, you can reduce manual labor, minimize waste and achieve optimal sorting results.

The machine delivers unmatched performance and reliability for industries seeking excellence in processing, ensuring clean, high-quality output every time.