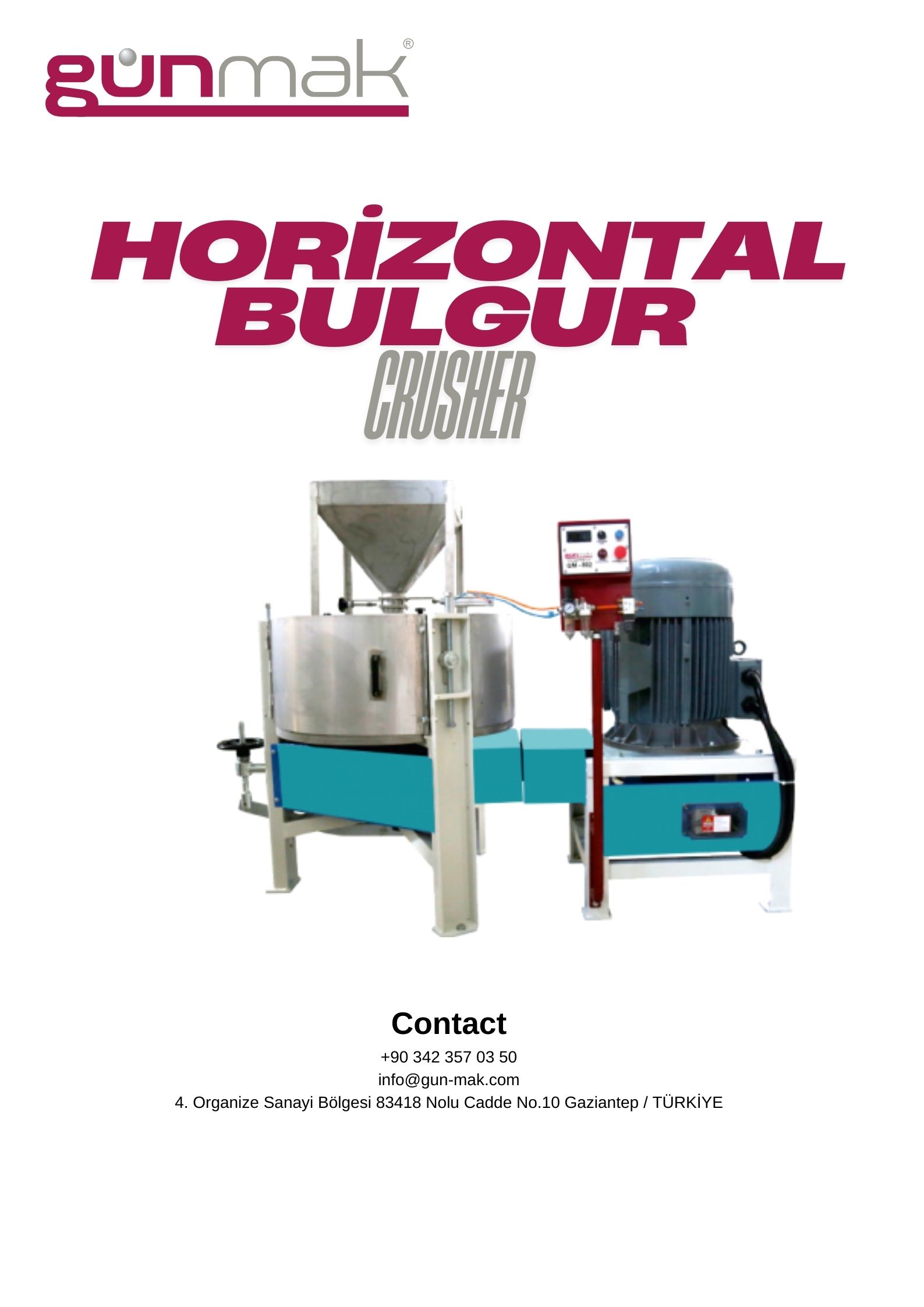

Horizontal Bulgur Crusher

A Horizontal Bulgur Crusher is a specialized machine designed to crush bulgur grains efficiently. This equipment is essential in the grain processing industry, ensuring that bulgur is processed to the desired size and texture for various culinary applications. By utilizing advanced technology, the Horizontal Bulgur Crusher enhances the overall quality of the bulgur.

How Does a Horizontal Bulgur Crusher Work?

The operation of a Horizontal Bulgur Crusher involves several key steps:

- Feeding: Whole bulgur grains are fed into the machine’s hopper.

- Crushing Mechanism: The machine employs horizontal rollers or blades that crush the grains to achieve the desired consistency.

- Separation: After crushing, the bulgur is sifted to ensure uniformity in size, separating any larger particles.

- Collection: The processed bulgur is collected for packaging or further processing.

Benefits of Using a Horizontal Bulgur Crusher

- Efficiency: This machine significantly speeds up the crushing process, saving time and labor costs.

- Consistent Quality: The Horizontal Bulgur Crusher ensures uniformity in grain size, which is crucial for cooking and baking.

- Durability: Built with high-quality materials, this machine is designed for long-term use with minimal maintenance.

- Versatility: Suitable for various types of bulgur, making it a valuable asset in any grain processing facility.

Applications of Horizontal Bulgur Crushers

Horizontal Bulgur Crushers are widely used in:

- Food Industry: Essential for manufacturers producing bulgur for retail and food service.

- Culinary Uses: Used in restaurants and food businesses that require high-quality bulgur for their dishes.

- Export Markets: Ensures that bulgur meets international quality standards for export.

Conclusion

The Horizontal Bulgur Crusher is a vital tool in the bulgur production process, enhancing efficiency and quality. By understanding its operation and benefits, businesses can optimize their bulgur processing and better meet consumer demands.