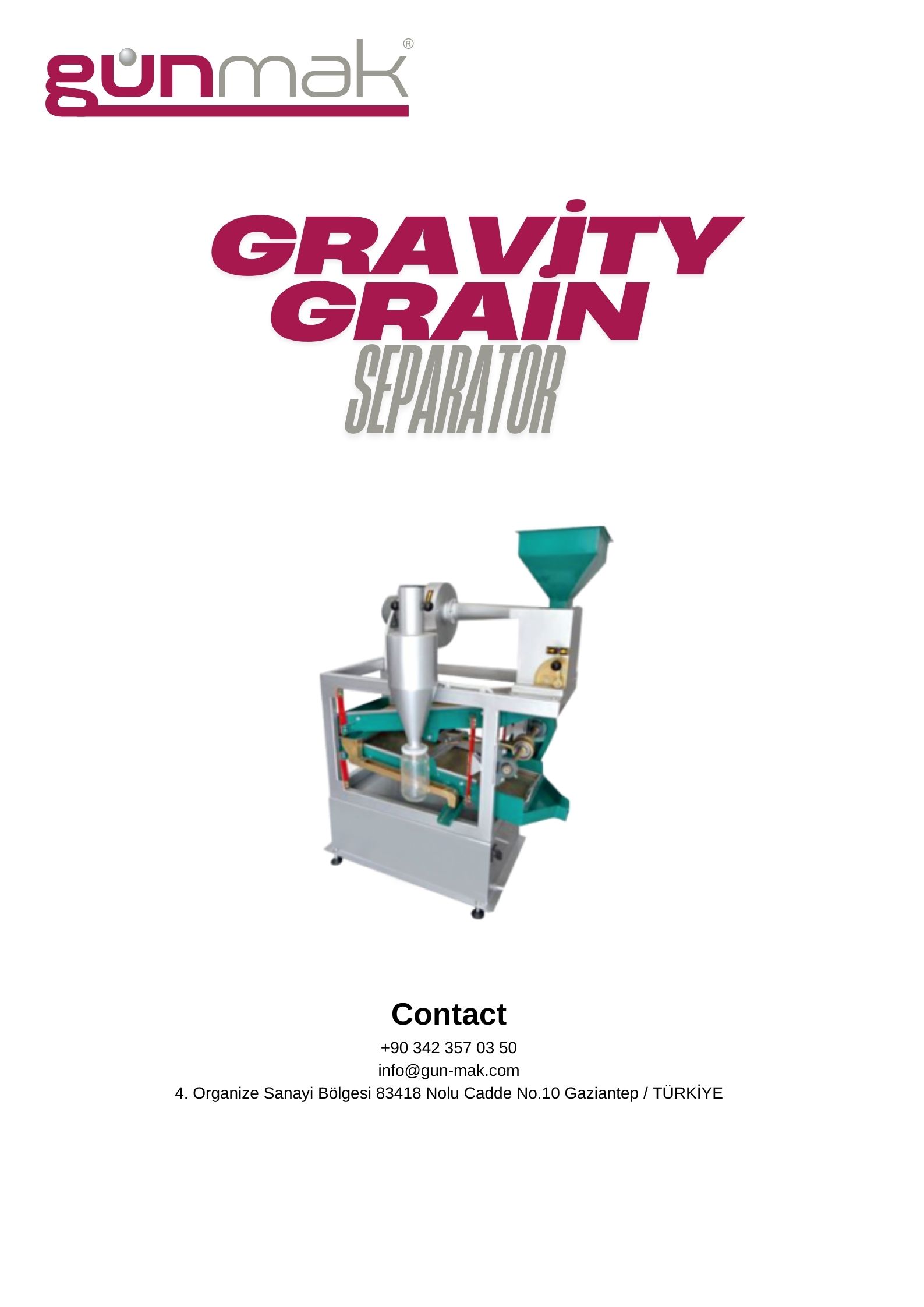

Gravity Grain Separator

A gravity grain separator is a specialized machine used in the grain processing industry to separate grains based on their weight and size. This equipment plays a crucial role in enhancing the quality of bulgur during the polishing process by effectively removing impurities and ensuring uniformity in the final product.

How Does a Gravity Grain Separator Work?

The operation of a gravity grain separator involves several key steps:

- Feeding: Grains, including bulgur, are fed into the separator.

- Airflow and Vibration: The machine uses controlled airflow and vibration to create a fluidized bed of grains, allowing lighter impurities to be separated from heavier grains.

- Separation: As the grains move through the separator, they are sorted based on weight and size, ensuring that only high-quality bulgur is processed further.

- Collection: The separated grains are collected in different compartments for further processing or packaging.

Benefits of Using a Gravity Grain Separator

- Enhanced Quality: The separator effectively removes impurities, improving the overall quality of bulgur.

- Increased Efficiency: Automating the separation process saves time and reduces labor costs, allowing for higher production rates.

- Uniformity: Ensures that bulgur grains are of consistent size and weight, which is crucial for cooking and processing.

- Versatility: Suitable for various grains, making it a valuable asset in any grain processing facility.

Applications of Gravity Grain Separators

Gravity grain separators are widely used in:

- Food Industry: Essential for manufacturers producing high-quality bulgur and other grains.

- Culinary Uses: Used in restaurants and food businesses that require premium bulgur for their dishes.

- Export Markets: Ensures that bulgur meets international quality standards for export.

Conclusion

The gravity grain separator is an invaluable tool in the bulgur polishing process, enhancing the quality and efficiency of grain processing. By understanding its operation and benefits, businesses can optimize their bulgur production and meet consumer demands effectively.